Blog article updated 4/14/2025 with updated pre-emergence herbicide information from coauthors Dr. Werle and Guilherme Chudzik

When I am asked a direct question from a farmer or a crop consultant my response is always as follows…Do you want the short answer or the long answer as I can say the same thing in 5 minutes or 5 hours. Their response to me is almost always the same…”Just the Facts Jack”. In this blog I will attempt to answer four very agronomically important and challenging questions in a very succinct manner. However as we all know brevity can be a gift or a curse depending upon the context of the question. With that being said here we go!

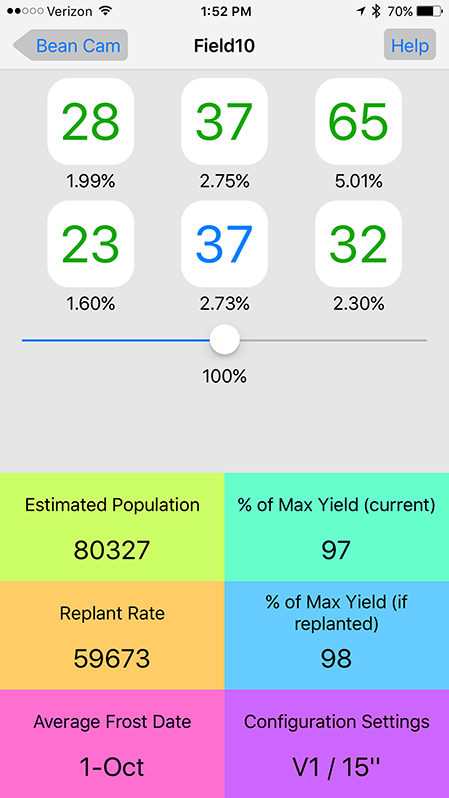

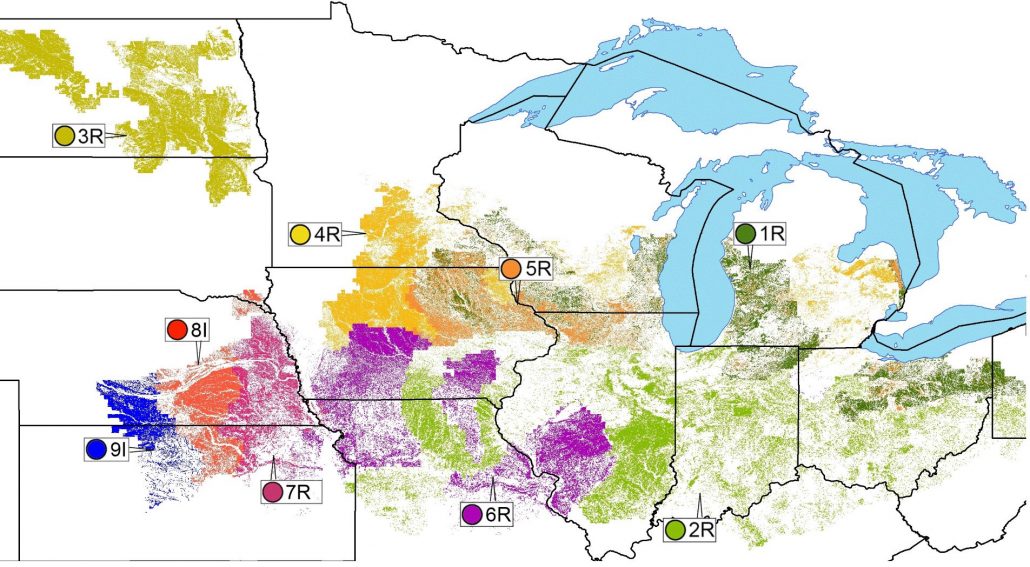

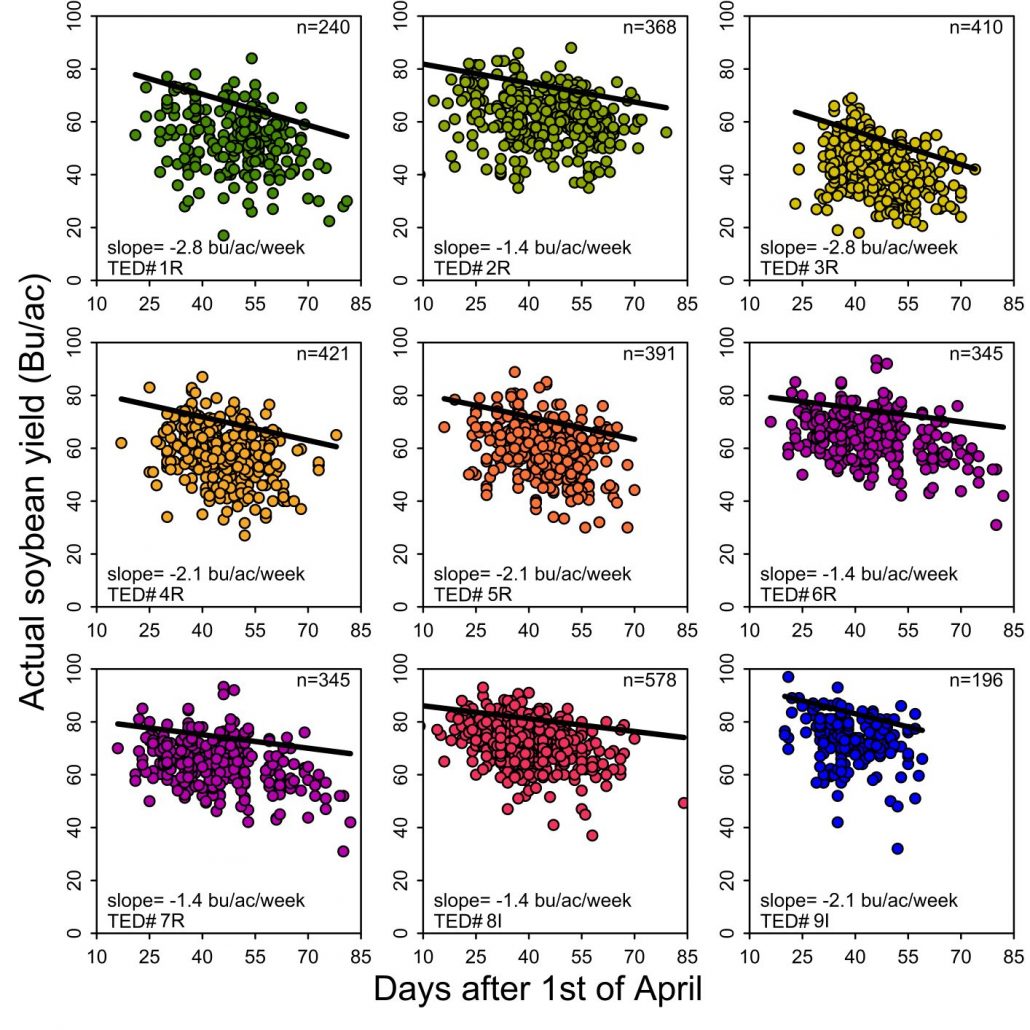

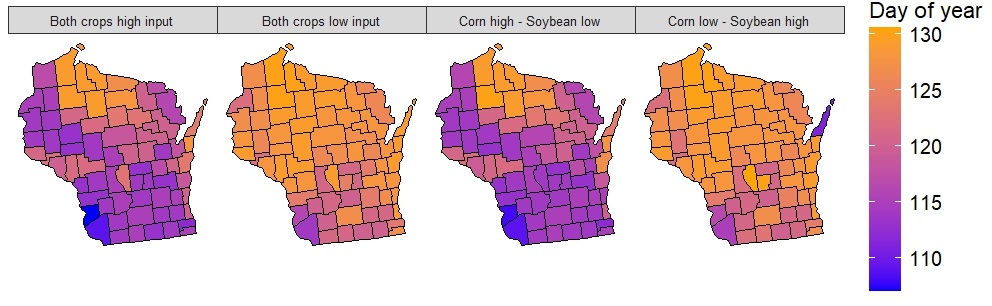

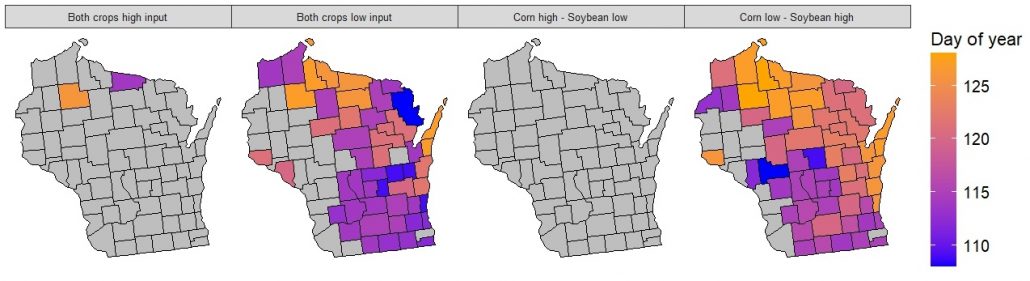

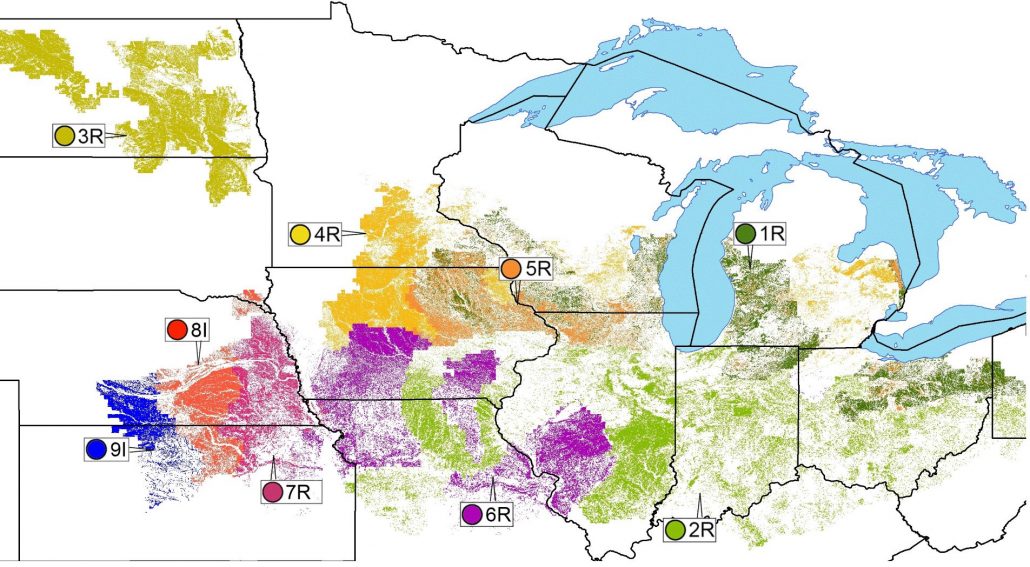

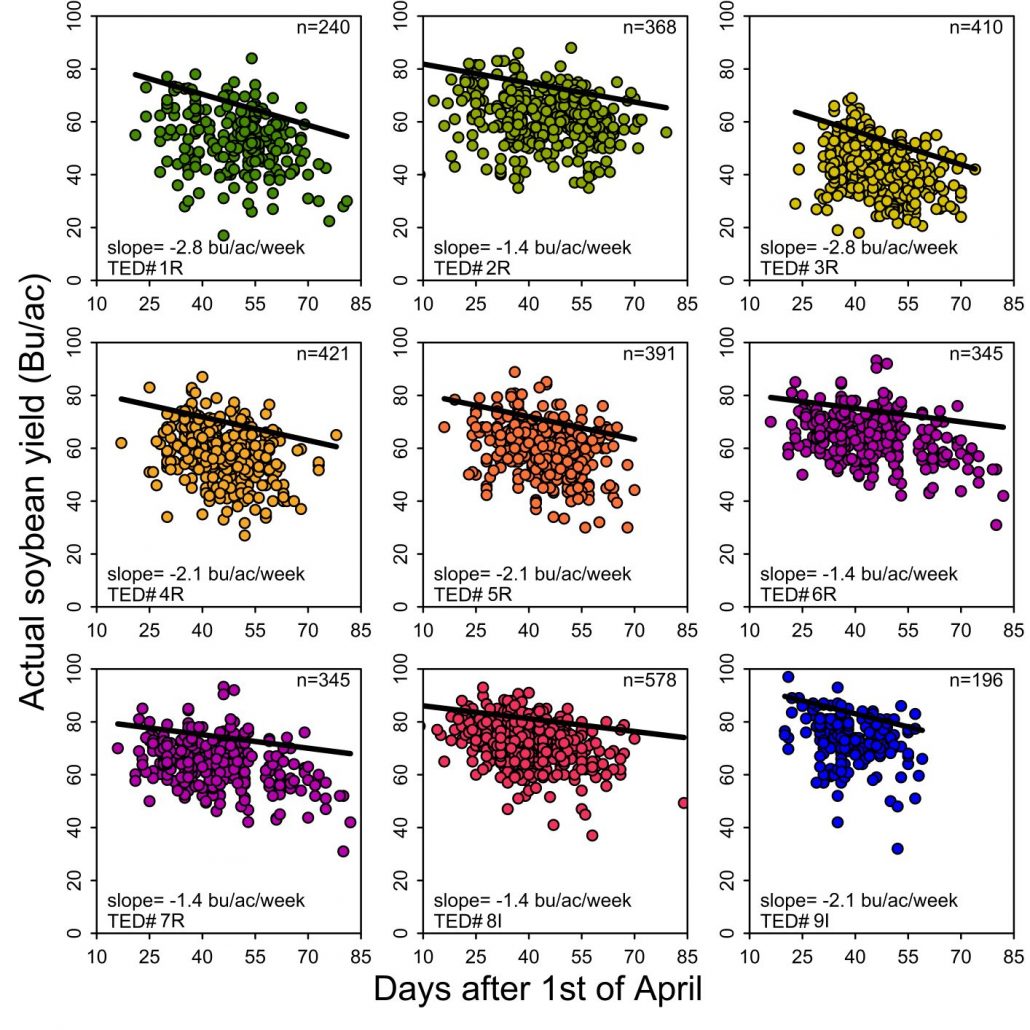

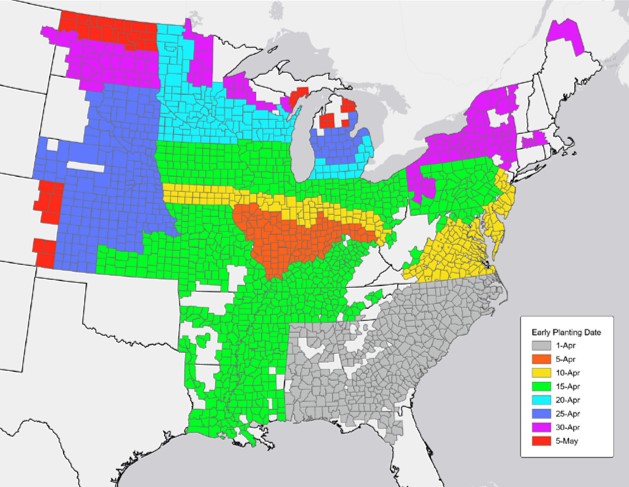

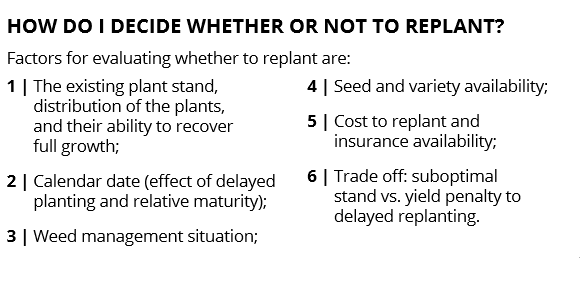

Question #1. When should I start planting soybean? My general response is to start planting your soybean crop ~7 to 10 days before you start putting your corn in the ground (maybe rethink this in 2025) with the caveat that the soil is fit and you are following your crop insurance replant dates (Please review updated RMA map). We have measured soybean yield loss due to delayed planting date as early as ~April 10th in parts of the Midwest however the rapid yield decline (up to 0.5+ bpa per day) occurs at ~May 10th. As you would expect the magnitude of this planting date yield response is soil and climate dependent and yield losses in some areas (TED’s) where as high as 2.8 bpa per week for delayed planting (Figures 1 and 2). For a deeper dig please review the below supplemental documents.

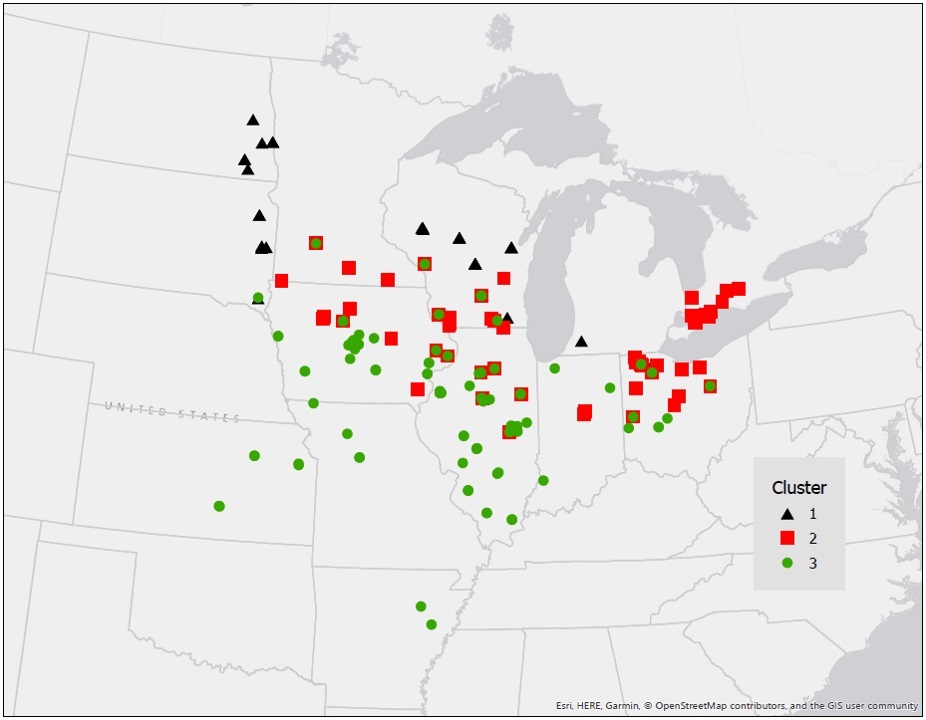

Figure 1. Map of the North Central US region showing nine technology extrapolation domains (TEDs) used in this analysis.

Figure 2. Producer soybean yield plotted against planting date in 9 technology extrapolation domains (TED) in the NC USA region.

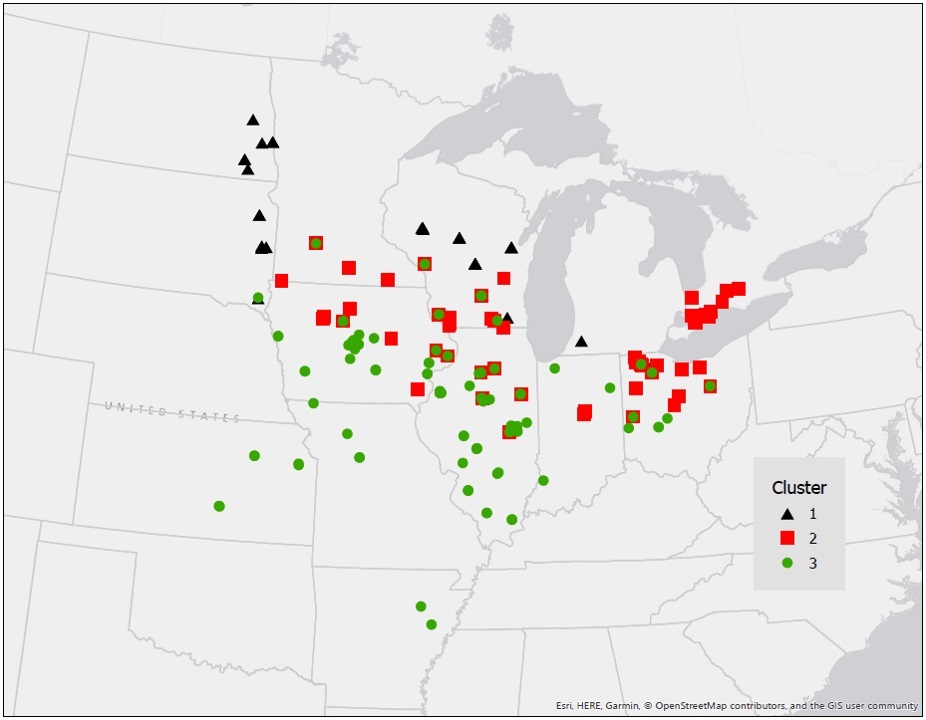

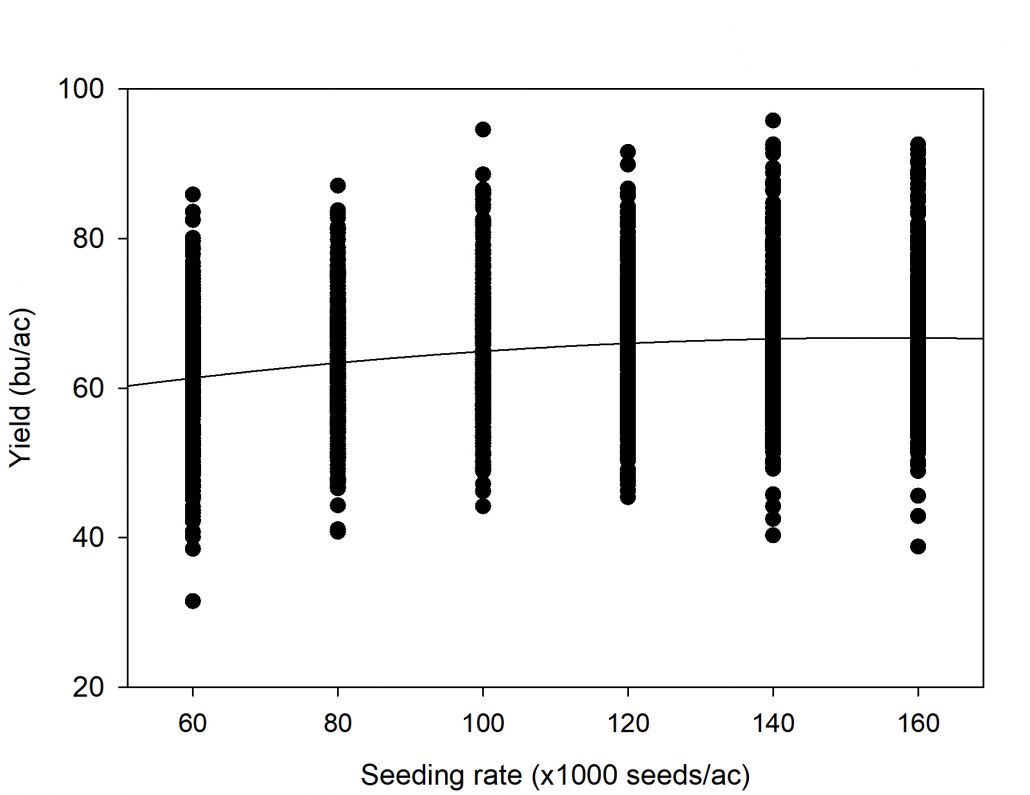

Question #2. What is the optimal soybean seeding rate? The quest for the optimal agronomic soybean seeding rate for yield vs. the optimal economic seeding rate has been an ongoing debate. Fortunately a large group of academics and industry (thank you Corteva) were able to combine data sets and address this question (Figure 3). Our results suggest that for “on-time” soybean planting dates the optimal agronomic soybean seeding rate to achieve 99% yield potential ranged from 237,000 to 128,000 seeds per acre (assuming 90% germ) across environments; whereas the optimal economic soybean seeding rate ranged from 157,000 to 103,000 seeds per acre. Thankfully this roughly confirms my original recommendation that you buy a bag an acre (140K) and place ~20% more seed on the low yielding acres and ~20% less on the high yielding acres, especially in areas of high white mold concern. If planting is delayed however we do recommend that you increase your seeding rate accordingly (Adjust Your Seeding Rate (Higher) But Not Your Maturity Group For Late May Planted Soybean ). For a deeper dig please review the below supplemental document.

Figure 3. Location of 211 trial site-years that are included in the database and their respective environmental cluster classifications.

Table 1. Agronomic and Economic Optimal Soybean Seeding Rates by Environmental Cluster.

|

Cluster 1

|

Cluster 2

|

Cluster 3

|

| Yield level (bu a-1) |

Agronomic/(Economic) Optimal Seeding Rate1,2

|

| < 58 |

237/(133)

|

170/(136)

|

130/(103)

|

| 58 – 71 |

168/(138)

|

145/(157)

|

136/(121)

|

| > 72 |

154/(119)

|

128/(122)

|

142/(145)

|

1Agronomic optimal seeding rate (x1000 seeds) based on 99% maximum yield level.

2Economic analysis based on $62 a unit (140k) for seed and $9 a bushel pricing; soybean price and seed cost fluctuations will change the EOSR.

Question #3. When should I apply my pre herbicide?

The effectiveness of PRE-emergence herbicides is influenced by many factors including application time, soil type, weather conditions, and weed seedbank community composition and infestation level. The ideal time to apply a PRE herbicide is shortly before the onset of emergence of the target weed species followed by 1-2 inches of activating rainfall. But that’s often not the reality under field conditions.

For soybean planted in May, applying a pre-emergence herbicide at or shortly after crop planting is a standard practice and makes agronomic sense. Deciding when to deliver a pre-emergence herbicide to ultra-early planted soybean can be challenging though. One of the challenges is that some of the effective PRE herbicides for waterhemp control should be applied within 3 days of soybean planting according to their labels (e.g., flumioxazin, sulfentrazone). If soybean is planted in mid-April, and waterhemp doesn’t start emerging until mid-May, should a PRE still be sprayed in April within 3 days of planting? Or should a grower decide on a more flexible chemical program that allows for a later application?

Our recent research funded by the Wisconsin Soybean Marketing Board indicates that, in lighter soil (e.g., sandy loam, 1.6% O.M), residual herbicides dissipated faster compared to in silt loam soil (e.g., silt loam soil, 3.5% O.M). Moreover, herbicide dissipation was faster during the wetter spring of 2022 compared to the dry spring of 2023. What these results suggest is that applying PRE herbicides early, particularly in fields with lighter soils during wet years, may result in poor control of late-emerging weeds such as waterhemp and small-seeded annual grasses (e.g., foxtail species).

- Factors like soil type, weather conditions, and weed seedbank community composition and infestation level impact the effectiveness of PRE herbicides.

- Timing PRE herbicide applications strategically is crucial for successful weed control, particularly in ultra-early soybeans.

- In lighter soils, residual herbicides dissipate faster, thus application timing becomes critical to avoid reduced control and the need for multiple sprays to control late-emerging weeds, particularly during wet years.

Question #4. When do I use a soybean seed treatment? I purposely placed this questions last as I know it will draw significant ire; however the data are what they are. Soybean seed treatments should only be used in some early planted soybean situations and/or if you have a history of or have scouted for an insect (i.e. Bean leaf beetle) or a pathogen (i.e. SDS) that exceeds economic thresholds. For a deeper dig please review the below supplemental document.

Th-th-th-that’s all folks!

Figure 1. Soybean seed yield response to seeding rate for soybean planted in Late May and June in IA, WI, and SD.

Figure 1. Soybean seed yield response to seeding rate for soybean planted in Late May and June in IA, WI, and SD. For more detailed information regarding the factors above please see our full resource guide entitled:

For more detailed information regarding the factors above please see our full resource guide entitled: